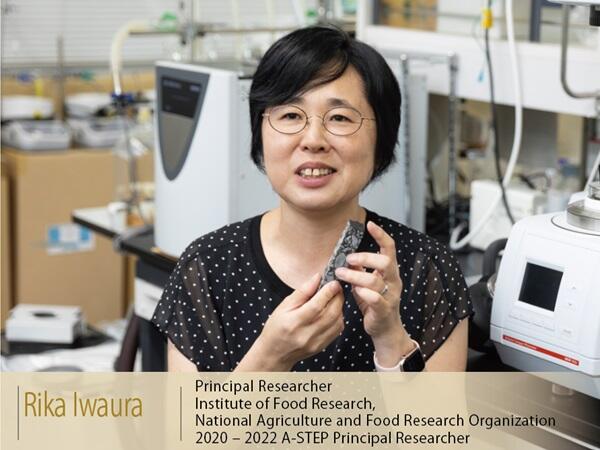

In the segment 'A Look Around Innovation,' we introduce research and development (R&D) sites that have led to social implementation. In this installment, we introduce Principal Researcher Rika Iwaura of the National Agriculture and Food Research Organization, who is exploring ways to extend the lifespan of asphalt pavement by introducing a starch-derived gelling agent for organic solvents to maintain hardness at high temperatures.

Exploring new applications for new materials — Small talk leads to a focus on roads

Tsukuba City in Ibaraki Prefecture has been developed as a science city since the 1960s. The city overlooks Mt. Tsukuba, known locally as the "Fuji of the east," and is home to a number of institutions dedicated to physics, chemistry, biology, and earth science, where R&D is conducted with an eye toward the next generation, such as the social implementation of technology and promotion of sustainable development goals (SDGs). Among these institutions, the National Agriculture and Food Research Organization (NARO), located in the southwestern part of the city, is the largest research organization in Japan dedicated to agriculture and the food industry, employing more than 1,700 researchers. A project to support Japan's infrastructure with starch has recently been launched at the Institute of Food Research of NARO.

Starch is a carbohydrate whereas infrastructure is a social foundation, meaning that the correlation between the two concepts is not readily apparent. Nonetheless, as a principal researcher at NARO, Rika Iwaura is aiming to connect the two to the lifespan of infrastructure. Starch is the Organization's area of specialty. Iwaura has been working with SUNUS Co., Ltd., (Kagoshima City), a manufacturer that has technology to produce the carbohydrate 1,5-anhydro-D-glucitol (AG) from starch, to develop products that take advantage of this technology.

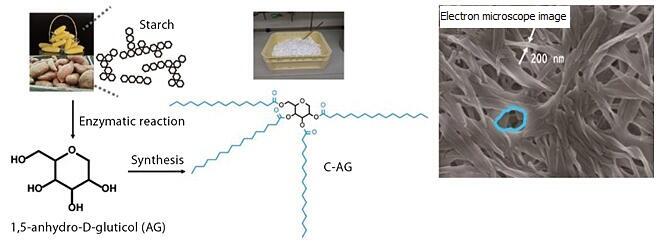

Iwaura's group has succeeded in synthesizing a new substance called C-AG, a fatty acid linked to AG (Figure 1). "C-AG functions as an oil gelling agent that encapsulates a wide variety of organic solvents and increases their viscosity. It is also easy to manufacture, has low toxicity to living organisms, and the gelation process has the advantage of low temperature of less than 100℃. A wide range of applications are expected, including thickening of cosmetics and pharmaceuticals," she says enthusiastically about the appeal of C-AG.

Figure 1: Structures of C-AG and C-AG gel

While considering applying for the JST A-STEP project in 2020, Iwaura was looking for collaborators to develop applications for C-AG. In the process, she focused on its use as an asphalt modifier for road pavement. Asphalt, the distillation residue of crude oil, is normally highly viscous, but becomes more fluid at high temperatures. It acts as an adhesive between aggregates in road pavements. As the temperature of the road surface increases, asphalt becomes more fluid, and the road surface becomes soft. Consequently, vehicles may leave uneven wheel marks, necessitating repair work to maintain a smooth surface.

Iwaura first turned her attention to asphalt and its challenges when she had an encounter at an international gathering of academic researchers related to colloids and interfaces. After giving a presentation on the gelation of C-AG, she had the opportunity to speak with an employee of a company involved in asphalt paving. "During our chat, I heard that asphalt is a kind of colloid and that surfactants are used to improve its functionality. I felt a strong affinity with asphalt as a research subject for the first time, and I came up with the idea of using C-AG as a surfactant to improve functionality."

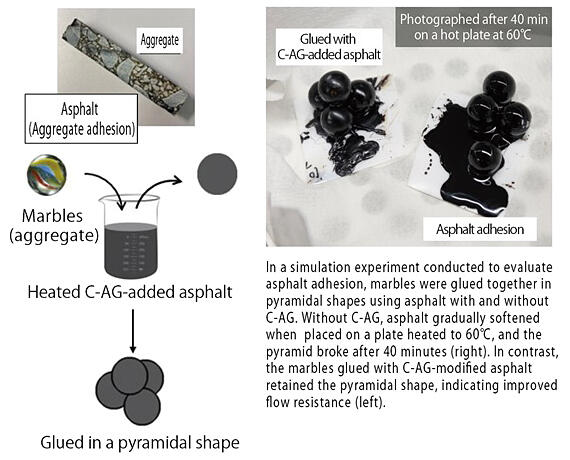

Figure 2: Adhesion experiment of C-AG-added asphalt

Tackling environmental challenges in A-STEP: Difficulty in procuring single kilogram samples

Conventionally, asphalt modifiers are introduced to increase flow resistance and prevent the road surface from softening even at high temperatures. However, to improve the flow resistance of modified asphalt, high-temperature treatment is required during manufacturing and construction. For example, the petroleum-derived styrene-butadiene thermoplastic elastomer (SBS), which is often used as a modifier, requires processing at approximately 180℃.

This not only makes the working environment harsher, but consumes more energy, leading to an increase in CO2 emission. Iwaura had a hunch that this is where C-AG can come into play. "If we can lower the temperature at which modified asphalt can be manufactured and constructed, the lifespan of asphalt pavement can be extended without concern for the working or global environment." In 2020, the project was adopted by A-STEP as the "Creation and functional expression of starch-based oil gel fiber."

Initially, A-STEP was to confirm the basic properties of C-AG to determine if it can encapsulate asphalt, an organic solvent, and turn it into a gel. Iwaura contacted every company that was able to sell her the crucial asphalt samples; however, she had some difficulty placing orders. "Ordinary orders are usually placed in units that require the use of tanker trucks. I explained the situation to the company and asked if I could purchase only the amount used in a laboratory, and I managed to get a kilo unit from one company," recalls Iwaura.

Manufacturing and construction become possible at low temperatures — Aiming for cost reduction and mass production

When a container containing asphalt and C-AG was placed in an oven heated to 130℃ for 30 minutes and then stirred for 30 seconds, C-AG successfully encapsuled the asphalt and turned it into a gel. It did not separate again when left to stand at room temperature (Figure 2). These properties were confirmed by atomic force microscopy, which is suitable for observing minute structures. The observation revealed that C-AG-added asphalt has fibrous structures dispersed throughout it. The solvent is encapsulated between these structures, forming a gel.

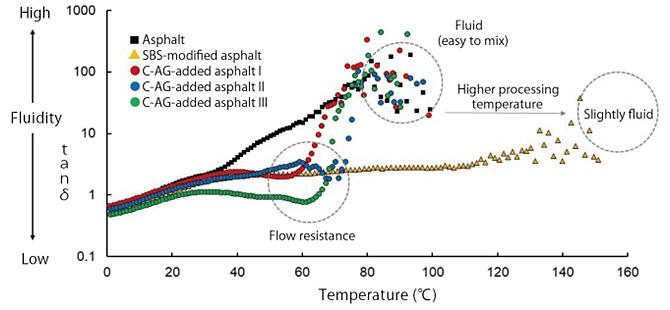

Iwaura also worked on the evaluation of flow resistance and fluidity. Three types of asphalt were evaluated: (1) asphalt, (2) SBS-added asphalt, and (3) C-AG-added asphalt. For each asphalt type, fluidity was measured between 0 and 160℃. Because the asphalt surface temperature can reach approximately 60℃ in extremely hot weather, the asphalt must be flow-resistant up to this temperature. (3) was observed to be resistant to flow up to approximately 60℃, and its fluidity increasing to that of standard asphalt at approximately 80℃, making it easier to process (Figure 3). In other words, the possibility of manufacturing and constructing at lower temperature than SBS was realized.

Iwaura says that R&D for social implementation is still in the middle of the road. This is because several issues remain to be considered. "For example, can flow resistance be maintained up to the temperatures required for practical use? Are there any problems with weather resistance and recyclability? We are still investigating these issues." Her future goal is to establish a joint research system with a view to the supply chain, with the objective of developing mass-production technology and realizing cost reductions. Iwaura continues to strive toward the day when starch becomes useful for infrastructure.

(TEXT: Shunsuke Mogi, PHOTO: Hideki Ishihara)

Figure 3: Dynamic viscoelasticity evaluation of C-AG-added asphalt