In the segment 'A Look Around Innovation,' we introduce research and development (R&D) sites that have led to societal impacts in the future. In this 8th installment, JST News paid a visit to Professor Makoto Ashiuchi and Special Researcher Yuichi Hakumai of the Multidisciplinary Science Cluster of Life and Environmental Medicine Science Unit of the Faculty of Education and Research at Kochi University. They have been working on the development of a medicinal plastic material (possessing antimicrobial and environment-compatible properties) from natto mucilage, and a bio-venture company was established to challenge its social implementation.

A university-launched venture company established at Kochi University that develops materials made of biopolymers

Bordered by the Shikoku Mountains in the north and the Pacific Ocean in the south, Kochi Prefecture boasts the highest horticultural agriculture productivity in Japan. Kochi University's Monobe Campus, located within a short 15-minute walk from Kochi Ryoma Airport, serves as the entrance to the prefecture. The Faculty of Agriculture and Marine Science of the same is located here. In April 2023, a university-launched bio-venture company "PlastiFarm" was established. The representative director of this company is Professor Makoto Ashiuchi of the Multidisciplinary Science Cluster of Life and Environmental Medicine Science Unit, the Faculty of Education and Research at Kochi University.

Ashiuchi, who joined Kochi University in 1994, has investigated about the chemistry of biosynthesized polymer molecules, called "Biopolymers". These are elongated molecules that contain proteins and nucleic acids (i.e., DNA and RNA), essentially synthesized by living cells. Because all the catalysts and syntheses occur under the habitable conditions of living cells, the biosynthesized polymers are beneficial in biological safety and further environment-compatibility, compared with the chemically synthesized polymers using petroleum and so on. Biopolymers have been increasingly focused on the fields of modern materials science and polymer engineering.

Our daily lives virtually rely on the chemo-synthesized polymers, whose products such as cloths and plastics have been required to date. Fossil resources are however not sustainable. Further, plastic waste may impact against ecosystems (particularly worldwide oceans), because "microplastics" hardly decompose in the natural world. Ashiuchi explained, "By developing and implementing a new bioplastic environment-compatible-plastic material made from biopolymers, we aim to contribute to solving the ocean plastic waste problem and realize a sustainable society. This led to the establishment of PlastiFarm."

Working with Ashiuchi on the R&D of PlastiFarm as a research director in the same unit at the same university is Special Researcher Yuichi Hakumai. When Hakumai visited Ashiuchi's laboratory as a student, he was shocked by the research subject he observed. It was "natto" (fermented soybeans). He recalled with a smile, "I was both surprised and intrigued by the fact that polymer materials could be produced from familiar fermented food. This led me to assist Professor Ashiuchi's research."

The molecular structure of toothpaste provided a significant clue: Success in the development of water-resistant materials

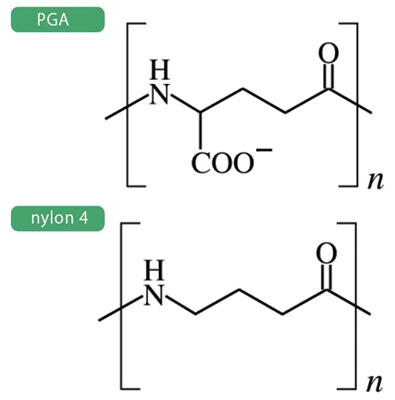

An ingredient of natto mucilage "poly-γ-glutamate (PGA)" was the key compound to develop a new material. Ashiuchi found the structural resemblance of PGA with nylon (a type of plastic) and had the PGA-plasticization projects (Figure 1). Before its materialization, the extraordinary water-solubility of PGA was primitive issue. Indeed, some PGA-gelation protocols have been archived; however, its plasticization and fabrication (thus, usual materialization) were attempted with no success to date.

Figure 1:Molecular structures of PGA and nylon 4

Chemical modification is commonly used in the functionalization of many biopolymers, particularly polysaccharides (e.g., cellulose). Ashiuchi attempted to solidify PGA based on chemical modifications (esterification) as well. Such a common methodology, however, did not provide any clues and he even considered discontinuing this project. What saved him was that the toothpaste that his father-in-law used was favorable. The characteristic molecular structures of the ingredients listed in the toothpaste coincided with the unit structure of PGA. This served as a significant clue. "In the midst of my research impasse, this clue was indeed a godsend."

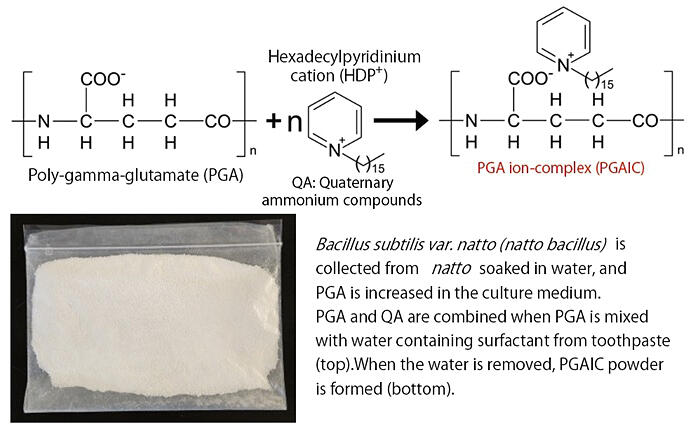

The components of toothpaste include a quaternary ammonium (QA) compound with a cationic moiety, having potential as amphipathic molecules. By combining this QA with PGA, Ashiuchi succeeded in developing a new material, "poly-γ-glutamate ion-complex (PGAIC)," which exhibits high water resistance (Figure 2). In the process of extracting PGA from a natto culture medium, using the aforementioned PGAIC-synthesis technology, he has also established a technology that enables recovery and mass production in a simple and cost-effective manner (at approximately 1/100 of the cost of conventional methods).

Figure 2:Development and manufacturing of PGAIC

Next, Ashiuchi worked on converting PGAIC into plastic components. He found that PGAIC exhibited antibacterial and antiviral effects, blocking over 99.9% of enveloped viruses. Additionally, he discovered the potential for "medicinal plasticization," combining antimicrobial and environment-compatible properties, which were traditionally considered mutually exclusive. During that time, demand for antibacterial and antiviral materials was growing worldwide due to the marine plastic problem and the spread of COVID-19 infections. Then, Ashiuchi and colleagues optimized elemental technologies for the medicinal plasticization of PGAIC as a part of their research subject. This research project was adopted by JST's A-STEP program in 2020.

The A-STEP project worked on the development of coating technology to utilize PGAICs in public health to prevent contact infections. Consequently, they were able to expand the number of synthesizable PGAICs to 11. The fundamental information required to extend the functional properties and applications of PGAICs is also now in place. It was additionally confirmed that PGAICs not only inhibit the growth of coronaviruses, influenza viruses, Escherichia coli, and fungi, but also exhibit antimicrobial properties at high temperatures and are highly resistant to washing. Hereafter, the company plans to market the product as a spray-type disinfectant.

Leveraging two sides of the same coin to aim for a sustainable society

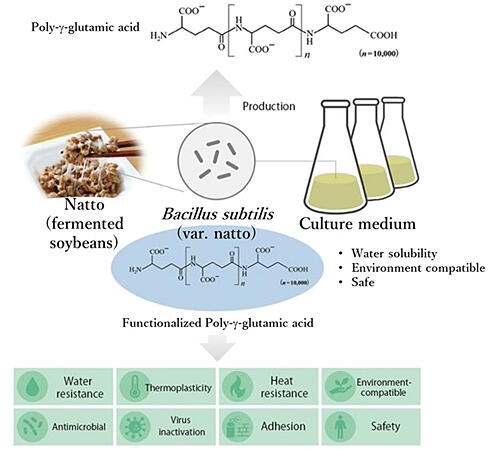

Such functionalized PGAs are characterized via multiple versatilities, including environment-compatibility and adhesiveness (Figure 3). Moreover, A-STEP's research is taking advantage of these features properties to blend the PGAs with polyesters, indicating a wide range of applications (e.g., coatings, fibers, and bottles). This R&D is also connected to PlastiFarm's business, and the company has been receiving several inquiries from textile manufacturers and other companies. PlastiFarm has also been selected as the first recipient of investment from an investment fund that supports university-based start-ups in Kochi Prefecture.

Figure 3:Characteristics of PGAIC

Usually, the antimicrobial and environment-compatible abilities of PGAIC may be thought to be mutually exclusive. Ashiuchi emphasized, "Antimicrobial and environment-compatible events seem like two sides of the same coin, because both are based on the concept called "microbial affinity", as seen in natto mucilage (namely PGA) that attracts microorganisms and causes them to adhere. Although the former implicates that microorganisms are killed by materials and the latter means that they eat materials, they both start after the collision of microorganisms with materials. Commonly, the magnitude of net effectiveness (i.e., the leverage of "microbes killing" and "materials degradation") would be proportional to the sustainability in collision (in other words, the period of contact) between microorganisms and materials, just revealing the valuation of microbial affinity of PGA and PGAICs with physicochemical adhesion. Our findings on the transformation of antimicrobial PGAICs into environment-compatible PGA will hopefully contribute to social sustainability in future."

To achieve this, he believed it was necessary to have the ability to assess the current situation and the power to take on challenges by trusting one's intuition. He cited "jitsu-sane-" as a keyword. "Sane" is an ancient Japanese wooden construction technique wherein wood is joined together by forming projections and recesses on the surfaces of wood materials. He stated, "Through the bold and innovative idea of intentionally adding irregularities to neatly arranged surfaces, Japan has been able to create several world-renowned architectural masterpieces, such as Horyu-ji Temple. By first envisioning the desired future look and then reverse-engineering to think about what steps should be taken, it is possible to generate truly fruitful innovations." Ashiuchi's persistent research will continue.

(TEXT: Manami Yokoi, PHOTO: Hideki Ishihara)