Professor, Department of Mechanical Engineering, Faculty of Engineering Science, Kansai University: 2020-23 A-STEP Principal Investigator

In the segment 'A Look Around Innovation,' we introduce research and development (R&D) sites that have led to social implementation. In this 13th installment, we introduce the efforts of Professor Takeshi Ito of the Department of Mechanical Engineering, Faculty of Engineering Science, Kansai University. He focused on nanospikes − i.e., the microscopic protrusions on the wings of cicadas − and developed artificial structures for practical application as new, drug-free antibacterial and bactericidal materials.

Wondering if such a thing really happened: Reproduced by nanoprocessing and confirmation of bactericidal effect

Kansai University's Senriyama Campus is located in a hilly area in Suita City, Osaka Prefecture. JST News visited the leafy campus to meet Professor Takeshi Ito of the Department of Mechanical Engineering, Faculty of Engineering Science, who is working on the development of new antibacterial and bactericidal materials conceived from cicada wings. Ito, whose research theme has been "biomimetics," a research area that builds on structures and functions of living organisms, came across an Australian research paper on "the antibacterial properties of cicada wings" in 2015, the year he became an associate professor at Kansai University. According to the paper, cicada wings have microscopic protrusions on their surfaces, and when a culture solution of Pseudomonas aeruginosa was dropped on the wings, the bacterium was killed by physical damage from the protrusions.

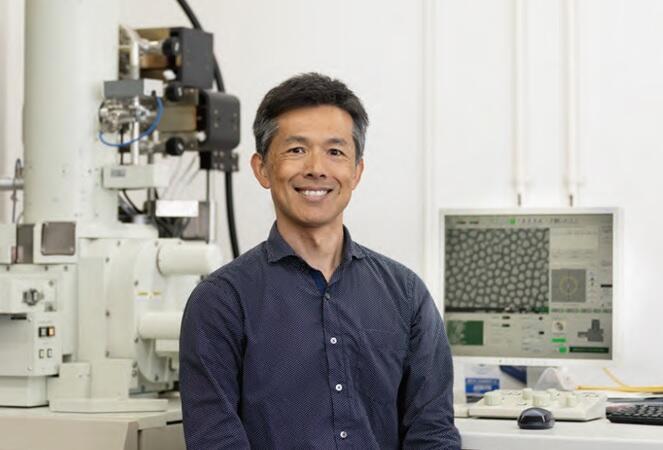

"I wonder if such a thing really happened, thinking that bacteria could not possibly die so easily, based on my experience with bacteria when I was a student," Ito said with a laugh. He actually caught a cicada (Cryptotympana facialis) on campus and observed it using an electron microscope. The surface of the wings was lined with regular rows of "nanospikes," which are protrusions of a nanometer scale. When a bacterial suspension was dropped on the wings, the protrusions indeed deformed and killed the bacteria. Ito assumed, "Based on this surface structure, it may be possible to create innovative antibacterial/bactericidal materials with minimal impact on the human body and environment (Figure 1)."

Figure 1:Cicada wing surface structure and Escherichia coli on nanospikes

Most existing antibacterial and bactericidal methods use drugs to chemically damage bacteria. The impact on the human body and environment and the emergence of drug-resistant bacteria have become major problems. The increase in resistant strains has adverse consequences, such as the refractoriness of infectious diseases to the drugs that were previously effective. In contrast, disinfection by nanospikes does not produce drug-resistant bacteria because it is a physical effect. The effect is considered to persist semipermanently as long as the structure exists. Therefore, Ito took on the challenge of artificially reproducing nanospikes to verify their antibacterial effects.

The Nano Physics and Engineering Laboratory, to which Ito belongs, possesses "metal-assisted etching technology" for nanoprocessing using metal catalysts and "colloidal lithography" for patterning using fine particles. Using these techniques, Ito fabricated nanospike structures on a 4x4 cm2 silicon substrate. He confirmed that E. coli in a culture solution dropped onto these silicon nanospikes was killed and filed a patent application for the fabrication of nanospike-structure-based antibacterial/bactericidal materials in 2018.

Shifting to soft and lightweight plastics — "Hardness" of protrusions is the key to effectiveness

Ito and his colleagues have successfully fabricated silicon nanospikes and demonstrated that they reduce the number of bacteria by a factor of up to 100,000. However, silicon substrates are suitable for fine processing to produce devices with small areas, such as semiconductors, and are expensive and difficult to handle due to their hardness. Therefore, they decided to fabricate resin nanospikes with a view of achieving their practical applications. Resin is soft, lightweight, and can be processed thinly, meaning that resin nanospikes have a wider range of applications, allowing their use over large areas and mass production.

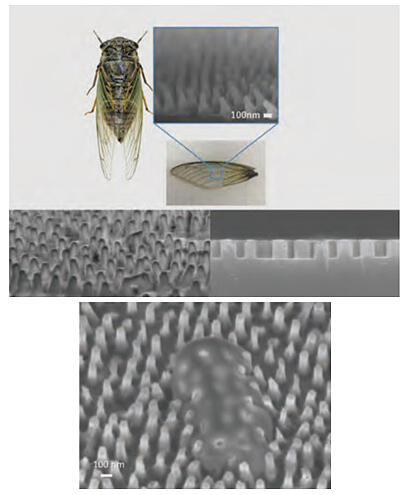

To achieve the fabrication of nanospikes made of resin, Ito applied for the A-STEP Industry-Academia Collaboration (Stage I) in 2020 as a principal investigator. After the adoption of the project, prototype resin nanospikes were fabricated. With the cooperation of the National Institute of Information and Communications Technology and the Kanagawa Institute of Industrial Science and Technology, a bactericidal test was performed by a method of differentiating between viable and dead bacteria using a fluorescent microscope, and an antibacterial test was conducted in compliance with Japanese Industrial Standards. However, in the early development stage, the bactericidal efficacy of resin nanospikes was not as high as silicon nanospikes. They searched for the cause of this problem by performing trial and error and found that the "hardness" of the protrusions was the key.

Because the bactericidal efficacy of the silicon nanospikes increased with the height of the protrusions, the resin nanospikes initially had the same protrusion height as the silicon ones. However, soft resin nanospikes with higher protrusions were found to be less effective in bactericidal assays because the protrusions were more easily bent. Therefore, the research team reexamined the height and shape of the protrusions that best fitted the resin nanospikes. Furthermore, they successfully identified a nanospike structure that was bactericidally effective (Figure 2). They also attempted to elucidate the mechanism by which bacteria die on nanospikes. "Initially, I thought that bacteria are killed because their cell membranes are damaged while they move around on the nanospikes," Ito said.

Figure 2:Example of the bactericidal effect of resin nanospikes

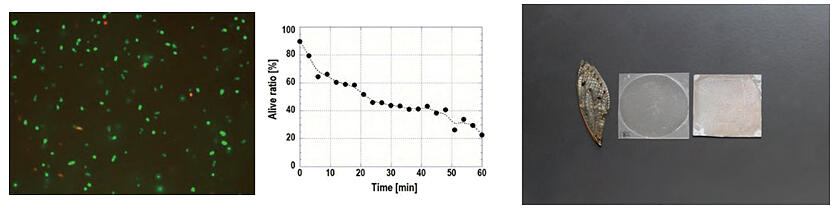

However, a research group in the U.K. presented a speculative theory that "the nanospikes just deform the cell membrane rather than piercing it, and the bacteria die because of the stresses caused by such deformation." In response, Ito advanced his analysis and formulated a hypothesis that bacteria die because the stress of cell deformation activates the membrane lytic enzyme "autolysin" in the cells. Based on this hypothesis, he conducted comparative experiments using normal E. coli and autolysin-deficient E. coli. As a result, it was found that the nanospikes were bactericidally less effective when autolysin-deficient E. coli was used or when autolysin was inhibited (Figure 3).

Figure 3:Results of comparative experiments between normal E. coli and autolysin-deficient E. coli

Expectations for infection control in, for example, evacuation centers: Plans for exhibition at Expo2025 and establishment of venture

The trial-and-error process, in which the resin nanospikes did not show bactericidal effects for a long time, led to new discoveries and ideas. "The reason why bacteria were not killed easily by the resin nanospikes was because the bacteria did not adhere well to their surface. Conversely, resin nanospikes are also antifouling and prevent themselves from being contaminated by bacteria and dirt," Ito explains. This property allows for applications in various fields. One such application is use in the medical field.

For example, infections via medical catheters are caused by cell colonies formed on the surface. However, it is difficult to apply chemical antibacterial and bactericidal agents into these devices because they are directly inserted into the body. If resin nanospikes are used, semipermanent antifouling medical catheters with no adverse effects on the human body can be achieved. Other expected contributions include improving the safety of food products and daily life through the use of nanospikes in, for example, components in food factories and hanging straps and handholds in public transportation and preventing infections in environments where frequent sterilization and disinfection are difficult through their use in, for example, bathrooms and toilets in evacuation centers during disasters.

The results of research by Ito and his colleagues have been publicized at university exhibition fairs and at JST's new technology presentation meetings. Also, the results have attracted the attention of many companies. An exhibition at Expo 2025 in Osaka, Kansai, Japan (Osaka-Kansai Expo) and the establishment of a university-launched venture for commercialization are planned. "We are now brainstorming with many people to discuss in what situations our technology can be put to good use," he said.

Moving forward, he plans to explore resin nanospike structures for optimal antibacterial and bactericidal effects, as well as to seek wider applications, such as exploring for conditions in which nanospikes also exert antiviral properties, and to conduct physical evaluations for practical use, such as resistance to breakage. We cannot wait to see how nanospikes will "spread their wings" in the future.

(Article: Shinji Moribe, Photography: Hideki Ishihara)