Japan Airlines (JAL), the Japan Aerospace Exploration Agency (JAXA), and other organizations have been conducting experiments to increase fuel efficiency by reducing air resistance by applying a coating with fine grooves on the aircraft surface. Following tests on domestic flights, the above-mentioned organizations have recently begun testing the proposed approach on international flights. The grooves have a "riblet" structure inspired by the shark skin, and they are an example of "biomimetics," the technique of mimicking the structures of living organisms to aid in manufacturing. The goal is to reduce fuel consumption and carbon dioxide (CO2) emissions. The application of a riblet film on the aircraft surface has been developed in Europe, while the coating is expected to offer advantages in terms of durability and other factors.

Provided by Japan Airlines

The "shark skin" coating was given its name because it is rough and has fine grooves, just like real shark skin. These grooves suppress turbulent eddies near the skin surface and reduce the frictional resistance of fluids (water and air). Consequently, sharks can save energy and swim faster. This property has been imitated to create the riblet structure, which is used in competitive swimming suits and other products.

JAL and JAXA, together with Owell, a major paint distributor based in Osaka, have been conducting research on painting riblets on the aircraft surface to reduce air resistance. The method uses a water-soluble mold to create a riblet structure directly on the paint film and is patented by Orwell and JAXA. The grooves have a width of approximately 0.1 mm and can reduce surface friction resistance by about 5%. According to JAXA officials, the weight and durability of the film are restricted when using film riblets. The coating will increase the aircraft weight by a very small amount, will not require major modifications, and will last for 8-9 years, the same as the paint.

Provided by JAXA

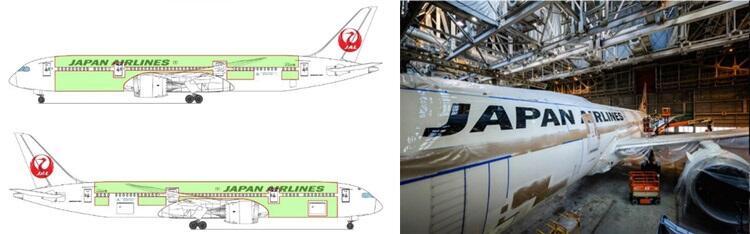

JAL verified the durability of the coating on a Boeing 737-800 aircraft used for domestic flights since July 2022. From November 2023, the coating area was expanded, and its effect on fuel efficiency was examined. Additionally, JAXA confirmed the effectiveness of the coating on a Boeing 787-9 aircraft used for international flights through wind tunnel tests and numerical analysis. Owell developed a coating system that handled large aircrafts. Based on these results, the companies decided to apply the coating to approximately 30% of the fuselage of 787-9 and to verify its performance in long-distance flights. The coating effect on fuel efficiency improvement, durability, and aesthetics will be investigated.

Provided by JAXA, JAL, and Owell

When this aircraft is operated as standard on the Narita-Frankfurt route, it is expected to reduce cruising resistance by 0.24%, decreasing fuel consumption by approximately 119 tons and CO2 emissions by about 381 tons annually.

At a press conference, Dongyoun Kwak, hub manager of the Aviation Environmental Sustainability Innovation Hub of the JAXA Aviation Technology Directorate, explained, "This time it is 30%, but we want to increase the application area and number of aircrafts on which the coating is applied. We will provide technical support."

(MARUYAMA Ryuichi / Freelance Writer)

Original article was provided by the Science Portal and has been translated by Science Japan.